Stainless Steel Double Tie Cable Looping Gripper with 300N Break Load for Hanging Systems and Lighting

Product Details:

| Place of Origin: | Guangdong, China |

| Brand Name: | W-mate |

| Certification: | RoHS |

| Model Number: | LG001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 |

|---|---|

| Price: | $0.35-0.50 |

|

Detail Information |

|||

| Material: | Stainless Steel | Type: | Wire Rope Clip |

|---|---|---|---|

| Model No: | LG001 | Color: | Alu+brass |

| Finish: | Natural Anodized+nickel | Style: | Double Tie |

| Wire Diameter: | 1.2-1.5MM | Break Load: | 300N |

| Size: | ∅3.9*20MM | Material Composition: | Brass+Alu |

| Gripper Type: | Double Gripper | Design: | Compact |

| Lock Design: | Automatic | Customization: | Available |

| Load Division: | Independent Gripper Mechanics | ||

| Highlight: | Stainless Steel Cable Looping Gripper,Double Tie Looping Gripper,300N Break Load Cable Looping Gripper |

||

Product Description

| Name | Looping Gripper / Double Gripper |

| Item No. | LG001 |

| Material | Brass + Aluminum |

| Color | Natural anodized / Nickel |

| Wire Recommendation | 1.2-1.5MM |

| Break Load | 300N |

| Size | ∅3.9×20MM (customized available) |

| OEM/ODM | Welcome |

| Application | For hanging systems, displays and lighting |

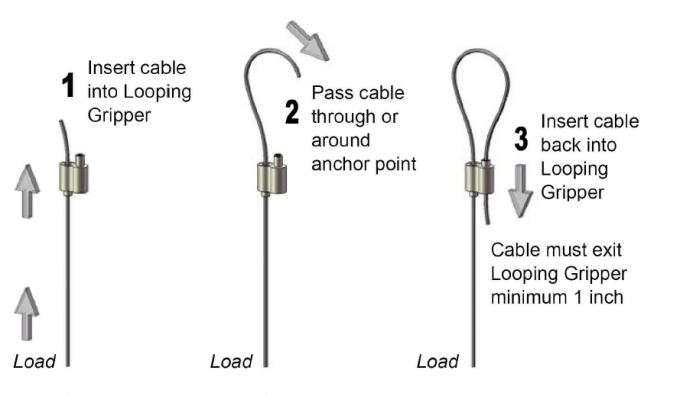

Our suspension kits feature double grippers with two independent gripper mechanisms that evenly distribute weight loads for secure fastening.

Available in three standard designs (all with copyright protection), these kits provide convenient, safe installation with minimal space requirements while enhancing visual appeal.

| Compact design | Easy to transport | Lower cost and more environmental protection |

| Various specifications | Suitable for different environments | Wide range of applications |

| Innovative automatic lock design | Easy to use | Improved work efficiency |

| Meets EU export requirements | Quality assurance | Higher safety performance |

| Own factory production | Professional application solutions | Efficient order to delivery process |

- Excellent R&D capability with advanced processing and testing equipment (40+ machines including cutting, welding, and casting machines)

- Complete inspection equipment and processes

- Customization available for materials, colors, and dimensions

- Professional QA team and superior after-sales service

We consider multiple factors including workload, safety requirements, environmental conditions, lifecycle needs, flexibility, and cost when designing solutions for specific applications.

We implement four-stage inspections before and after production with complete QC processes and solutions to ensure quality while controlling costs.

Please provide complete specifications including: Material, Diameter, Construction, Coating, Length, Packing, Quantity, and any special remarks.

Standard lead time is 15 days, with expedited options available for urgent requirements.

- Express (DHL, UPS, TNT, FedEx): 3-5 days

- Sea Freight: Contact us for port-specific details

- Client-designated agents: Provide contact details

With our strict quality control (defective rate < 0.2%), we replace small quantities during warranty. For batch issues, we repair/resend or discuss recall solutions as needed.